Navigating the complexities of aerospace supply chains

Emma Rothwell shares her expertise on managing aerospace supply chains with a focus on innovation, collaboration, and sustainability at Mettis Aerospace.Emma Rothwell, a seasoned procurement professional with nearly two decades of experience, has seen it all when it comes to the aerospace supply chain. Currently working at Mettis Aerospace, Rothwell talks about the industry’s dynamic landscape, driven by factors such as geopolitical instability, technological advancements, and the urgent push towards sustainability.

Rothwell’s journey in procurement began almost 20 years ago, sourcing tool steels for small injection molds. “I think it was this role that ignited my passion for procurement,” she recalls. Her career has taken her through diverse roles in construction and medical device manufacturing before she found her niche in the aerospace sector. “Playing a key role in buying and making things that go on airplanes is not only a job but a career-long passion,” she says. This passion has driven her through various roles and industries, each contributing to her extensive knowledge and expertise in procurement.

The past few years have been particularly tumultuous for the aerospace industry. The COVID-19 pandemic, followed by a strong rebound in air travel and increased military spending due to global geopolitical tensions, has created a volatile market environment. Rothwell noted that the industry’s resilience is being tested by supply chain disruptions, shipping constraints, and labor shortages. Despite these challenges, she remains optimistic about the future, emphasizing the importance of innovation and collaboration in overcoming these hurdles.

Throughout her career, Rothwell has never taken for granted the importance of relationships and the desire to work collaboratively to solve problems and find solutions. “I feel incredibly fortunate that I get to work alongside stakeholders that continually and consistently push the boundaries,” she says. This collaborative approach is a testament to those serving the aerospace industry, which demands the highest level of precision, reliability, and agility from its supply chain partners.

At Mettis, teaming up with suppliers like Seco has been a game-changer. Thanks to these partnerships, Mettis has been able to stay efficient and cut costs, even with the industry’s growing demands. Rothwell shared a standout example of Seco’s role right after Mettis landed a ten-year contract with a major aircraft manufacturer. Seco jumped in to help develop innovative solutions, including new machinery, tooling suites, and cutting-edge automation systems, all set up in a new service center at Mettis’s Redditch site. “Our goals were to boost cutting efficiency, shorten cycle times, and create a cost-per-part model,” Rothwell explains. “This partnership has been incredibly effective, tackling problems before we even knew they existed”.

This approach has been instrumental in maintaining Mettis’s position at the forefront of aerospace forging, machining, and assembling. The company’s components are so widely used that whenever you fly, you are likely to be on board an aircraft using Mettis manufactured parts.

One of the most pressing issues in the UK aerospace industry is the significant skills shortage.

One of the most pressing issues in the UK aerospace industry is the significant skills shortage.

Rothwell highlighted Mettis’ efforts to engage with the future workforce through education fairs and school visits and their apprenticeship program has seen promising uptake, with 12 new apprentices joining recently.

Rothwell believes that if the industry can empower the next generation with a combination of innovation and education, it can achieve a winning formula.

“Topics like AI, automation, and technology are likely to keep the next generation curious and hungry,” she says.

“Businesses need to focus on nurturing that talent by blending the energy and enthusiasm of apprentices with the skills of seasoned engineers”.

As the world races towards net zero emissions by 2050, the aerospace industry is under immense pressure to reduce its carbon footprint. Rothwell discussed the sector’s efforts to adopt more eco-friendly materials and processes, as well as the importance of strong supply chain partnerships in achieving sustainability goals. She acknowledged the difficulties smaller organizations face in keeping pace with these demands but stressed the need for robust infrastructure and advanced manufacturing techniques.

Effective supply chain management encompasses standardization and modernization to withstand the demands of build rates and future demand. Rothwell emphasized that businesses must be supported by robust supply chains that allow them to build the right ecosystem. “As infrastructure development is crucial for achieving net zero, it needs to embrace advanced manufacturing techniques to significantly reduce production costs and lead times,” she explains. This is a controversial topic in an aircraft builder’s world right now.

Rothwell is a strong advocate for the role of technology and innovation in transforming the aerospace supply chain. “Embracing innovation and believing in the importance of supply chain partnerships is crucial,” she says. The aerospace industry is increasingly dependent on driving solutions through technological advancements. Rothwell points out that integrating automation and advanced manufacturing techniques can significantly enhance productivity and efficiency. “We need to look at ways to maximize synergies, whether this is through the procuring of newly developed materials or improved processes,” she adds.

Rothwell also touched on the importance of data in driving the future of the aerospace industry. She believes that the key to success will be the accessibility and measurement of data, ensuring that it is available on a regular basis and used in a meaningful way. She mentioned the B Corp status, which some small organizations have worked to achieve, and noted that while it may take time for larger aircraft manufacturers to reach this status, the industry is starting to see the nuances and requirements of sustainability and ESG through the audit process.

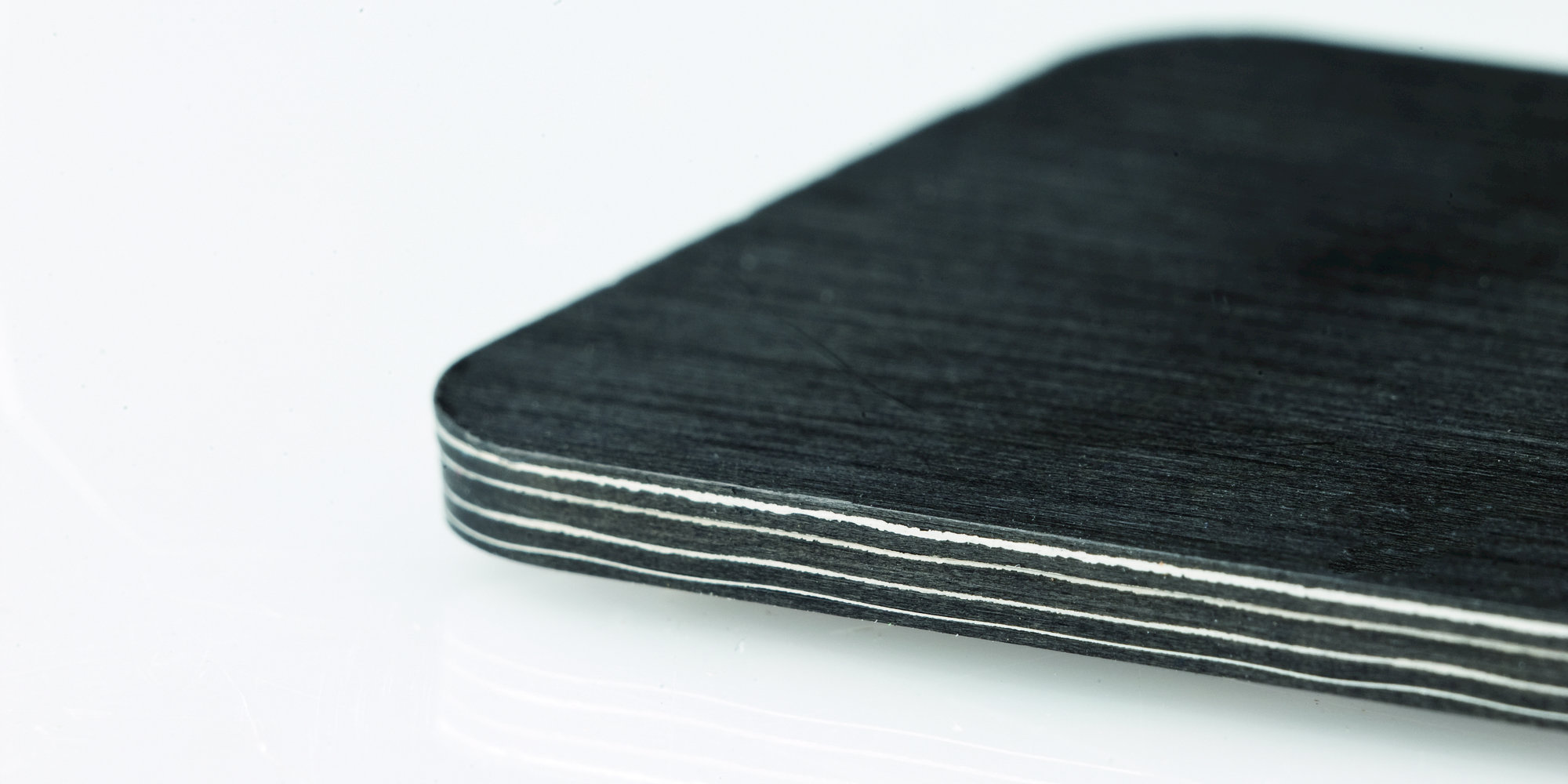

One of the key areas where technology is making a significant impact is in the development of new materials. Rothwell explains that the aerospace industry is constantly on the lookout for materials that are lighter, stronger, and more durable. These materials not only improve the performance of aircraft but also contribute to sustainability efforts by reducing fuel consumption and emissions. “The commitment by supply chain partners and the technology they can provide, including those technical advancements, are key to driving the future,” Rothwell emphasizes.

The aerospace industry operates in a highly volatile environment, with supply chain disruptions being a common occurrence. Rothwell notes that the industry has faced significant challenges over the past few years, including supply chain issues, pandemic recovery, shipping constraints, civil conflict, and mass layoffs. “A dynamic market landscape is a demanding environment to trade in, and the volatility is profound,” she says.

To address these challenges, Rothwell emphasizes the importance of having robust risk management strategies in place. Most aircraft builders have developed control towers, which have become essential tools to understand the risks within the supply chain and to form alliances that build resilience for future supplies. “The agility of the response and target times will be absolutely key in responding to such volatile demands,” Rothwell explains.

Rothwell’s insights provide a comprehensive overview of the current state of the aerospace industry and the challenges it faces. Her emphasis on innovation, collaboration, and sustainability highlights the key areas that industry leaders must focus on to navigate the complexities of the supply chain. As the aerospace industry continues to evolve, professionals like Rothwell play a crucial role in driving the sector forward, ensuring that it remains resilient and competitive in a rapidly changing world.

In conclusion, Rothwell’s experience and expertise provide a roadmap for industry leaders to navigate the challenges and opportunities that lie ahead. With a focus on empowering the next generation, adopting advanced manufacturing techniques, and building robust supply chains, the aerospace industry can achieve great things and continue to thrive in the face of adversity. “If our laser focus as a community of like-minded individuals remains at the heart of what we do, we are bound to achieve great things,” Rothwell says.

Inline Content - Survey

Current code - 5fce8e61489f3034e74adc64