ITI 2025 France - Inspiration Through Innovation: A three-day event focused on machining and collaboration

The 2025 edition of the ITI event in France brought together nearly 200 machining professionals in Bourges for technical demonstrations, specialized training and digital solutions to advance industrial production.A major French industry event, from June 3 to 5, 2025, the Seco France site in Bourges became a hub for innovation and industrial solutions. ITI – Inspiration Through Innovation – brought together nearly 200 professionals with a common goal: advancing machining through next-generation cutting tools and digital technologies.

ITI 2025 successfully gathered a comprehensive cross-section of French industry: customers, distributors, technology partners, and Seco teams were present. This diversity of profiles from aerospace, energy, medical, general mechanics, and defense allowed for the exchange of expertise, addressing real-world challenges with innovative solutions, and creating a genuine space for discussion around modern machining and production optimization.

ITI 2025 went beyond discussing innovation to focus on a practical and operational approach.

- Technical training on cutting tool wear and cutting parameter optimisation

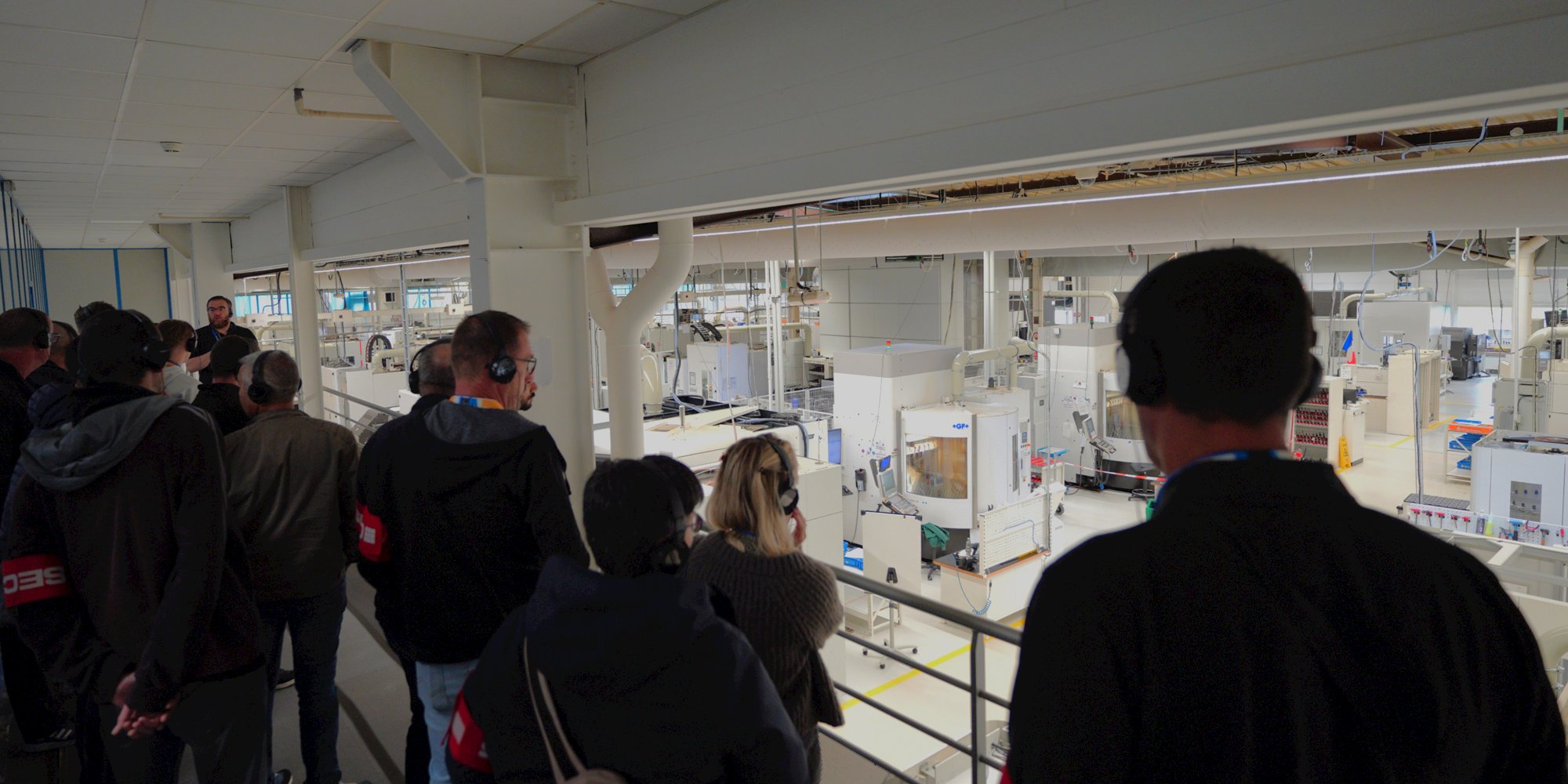

- Exclusive tour of the Seco Production Site and its technological innovations

- Part studies: ranging from accessible digital solutions to comprehensive turnkey approaches from design to machining

- Demonstrations and machining workshops in real conditions

- Collaborative exchange space with Seco's partners and, more generally, the Sandvik Group (Mastercam, TDM Systems, CGTech Vericut, Metrologic, Cribwise, Tebis)

The training sessions targeted critical issues in industrial machining, particularly the management of cutting tool wear—a key factor in production profitability. Through a proven methodology, participants explored the causes of premature wear, strategies for extending tool life, and levers for improving production cycles. The analogy with high-level sports highlighted the importance of rigor, method, and consistency in industrial performance.

To learn more about this topic, discover our full training program

Visitors also discovered the comprehensive support offered by Seco through project management (CET). From turnkey part studies to the optimization of machining strategies, including CAM simulation and technical documentation, each project benefits from personalized follow-up tailored to each sector's unique requirements.

Two complementary approaches were presented:

- Support by a dedicated team (CET - Component Engineered Tooling) for complex projects, including precise costing, technical documentation, and optimized machine programming.

- Autonomy through digital solutions: Suggest, MyDesign, Component Guidance, machine libraries, intelligent stock management, etc.

These tools enable industries from all sectors—aerospace, energy, medical, general mechanics, automotive—to gain efficiency, precision, and competitiveness.

Participants were able to compare their real-world issues with the proposed solutions in an environment that encouraged technical discussion. The focus was on collaboration between brands and technologies to improve manufacturing processes. This collaborative approach created a genuine forum for sharing experiences between machinists, where each sector of activity was able to benefit from the feedback of others.

First testimonials speak for themselves:

- "A perfect organization and enriching exchanges."

- "Very well-conducted workshops with concrete cases."

- "A useful, well-paced event, and very well received."

ITI 2025 confirmed that the evolution of industrial machining relies on the synergy between human technical expertise, technological innovation, and digital transformation. With an approach centered on the operational needs of manufacturers, Seco and its ecosystem of partners offer comprehensive solutions, from design to production.

ITI 2025 was a success thanks to the involvement of all Seco teams and partners, as well as the active participation of the professionals in attendance.

We hope to further enrich future editions and strengthen our support for our customers in their drive toward operational excellence.